Prime quality administration is an important aspect in just about every enterprise. It is essential to handle the usual of producing and firms equipped. The jewelry enterprise is believed for its consideration to factor and to ship flawless merchandise. Prime quality administration is an important think about jewelry manufacturing, because it’s essential to meet the expectations of consumers. Jewelry manufacturing facility prime quality administration procedures not solely cease defects and errors however as well as help to assemble perception

In jewelry manufacturing, prime quality administration should be maintained primarily based on jewelry manufacturing necessities. From selection of raw provides like gem stones or metals to final inspection of bijou objects. There are quite a few key elements for an environment friendly prime quality administration system. If attained and practices end in reaching superior prime quality in jewelry manufacturing.

Listed below are some most interesting practices that help to comprehend prime quality administration in jewelry manufacturing

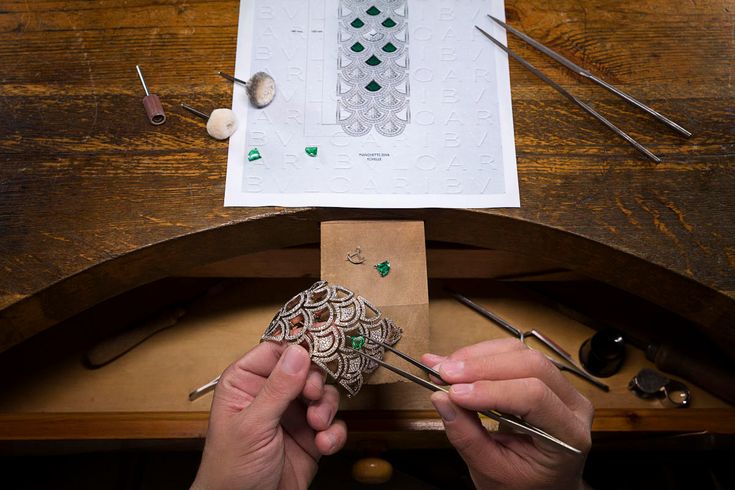

image credit score rating: pinterest

1. Design And Prototype Analysis

To handle jewelry manufacturing facility prime quality administration procedures, sooner than jewelry manufacturing begins, it is essential for factories to utterly assess the jewelry design. They need to check the design for its efficiency. It moreover should check the sharp edges of bijou objects and totally different prime quality points. They’ll moreover create prototypes to test the design of bijou objects and their efficiency.

You will have to evaluation the prototypes fastidiously and make modifications if obligatory. This prototype should be educated to the usual administration crew too. So that they will check it accurately sooner than transferring in course of the next step, which is mass manufacturing of bijou.

2. Supplies Inspection

Producers should make certain that the metals, gem stones, and totally different provides sourced for jewelry manufacturing meet the required jewelry manufacturing necessities. Jewelry manufacturing facility prime quality administration procedures moreover state how they should affirm the authenticity of gem stones and invaluable metals via the certification from suppliers. They’ll moreover check the purity and alloy composition of the metals.

If provides are sourced in bulk, producers can conduct random sampling exams. This helps to check the consistency and prime quality of raw provides. You will have to check out the purity and reliability of gem stones and metals sooner than exact manufacturing begins.

image credit score rating: pinterest

3. In Course of Inspection

To comprehend jewelry manufacturing facility prime quality administration procedures, factories ought to hold out widespread seen inspections. This helps to look out any seen defects in jewelry manufacturing objects. It might be defects akin to scratches or unsuitable gemstone placement or irregularities in plating. They should check the scale, weight, and proportion of each jewelry piece using micrometres and totally different items.

This ensures consistency regarding the prime quality along with quantity of the produced jewelry. There could also be moreover a step the place they need to check and study regarding the cracks, porosity, or totally different defects. Within the occasion that they stay away from these factors, it’d weaken the usual of bijou and compromise the usual and integrity of bijou.

4. Ending And Sharpening

One different jewelry manufacturing facility prime quality administration course of consists of inspecting all surfaces of bijou objects. It should be carried out by producers for checking smoothness. It moreover helps to check the sharpening and absence of another requirements. The jewelry objects should have a transparent, polished finish with none scratches or blemishes. Moreover it’s an integral part of inspection to check the plating and uniformity. It is required for plated jewelry, significantly. This helps to meet the jewelry manufacturing necessities.

image credit score rating: pinterest

5. Testing For Sturdiness

Producers should conduct and perform exams for durability primarily based on jewelry manufacturing facility prime quality administration procedures. It consists of checking the ability and hardness of bijou objects, akin to scratch exams for metals. The jewelry should be succesful to face as much as placed on and tear with out compromising the appears of bijou objects or function. They should moreover check for metals in the event that they’re non-allergic or reactive on pores and pores and skin. Notably when worn by prospects for a really very long time. This helps to take a security measure sooner than selling it accessible available in the market.

6. Remaining Inspection And Prime quality Assurance

There should be detailed final inspection and checking procedures sooner than supply and packaging of the product primarily based on jewelry manufacturing facility prime quality administration procedures. Each jewelry piece should endure a final inspection to guarantee that it meets design specs and necessities of top of the range, along with shopper expectations. They’ll moreover current obligatory certifications like metallic purity and gemstone authenticity throughout the packed objects.

It helps to create transparency and readability between purchaser and vendor. They’ll moreover preserve information of inspection, telling outcomes and corrective actions for future and sustaining jewelry manufacturing necessities.

image credit score rating: pinterest

7. Experience And Automation

For greater repairs of bijou manufacturing facility prime quality administration procedures, factories can implement devices like 3D printing or laser engraving for greater prime quality processes. It might probably moreover use automated inspection strategies for enhanced precision and effectivity in every design and jewelry manufacturing. They’ll moreover use software program program for monitoring every little bit of bijou produced via every step of producing. It ensures that nothing is prevented or missed throughout the prime quality check course of.

8. Recommendations Loop And Regular Enchancment

According to jewelry manufacturing facility prime quality administration procedures, producers can usually purchase and analyze ideas from prospects and retailers. This helps to find out any prime quality factors which will be recurring. This ideas collected or acquired is efficient belongings for enchancment in jewelry manufacturing. It might be used to reinforce designs, manufacturing methods, and administration prime quality procedures. Regular enchancment helps to forestall errors and refine prime quality in jewelry manufacturing necessities.

image credit score rating: pinterest

Discovering a top quality jewelry producer? Be part of via Maker’s Row

You will have to find probably the greatest companions that will help in reaching most interesting practices for jewelry manufacturing and manufacturing. Correctly, a easy route for finding a reliable affiliate is Maker’s Row. It is an web platform that not solely connects producers and producers based throughout the U.S. and from totally different worldwide areas however as well as helps discovering producers, along with from the jewelry enterprise too. Proper right here’s how Maker’s Row assists:

→ Maker’s Row provides an expert file of factories and producers specializing in different factors of bijou manufacturing. So if a producing facility has signed up and is listed on the platform, it helps to connect with jewelry producers and firms looking out for producers who’re professional to execute high-quality work and jewelry manufacturing necessities.

BOOK A DEMO WITH US

→ The entire manufacturing facility producers listed on the platform can showcase their corporations, custom-made jewelry designs, and gemstone certifications via their profiles. This transparency helps to connect with producers which will be on the lookout for most interesting practices in jewelry manufacturing.

→ Maker’s Row permits producers and startups to immediately work with factories that understand and prioritize prime quality administration. Thus, producers get the required jewelry manufacturing necessities for his or her jewelry line.

→ Jewelry producers can get right of entry to connect with the easiest high quality suppliers via the Maker’s Row platform, which thus helps in high-quality manufacturing, serving to producers to collaborate with factories that get hold of jewelry manufacturing facility prime quality administration procedures.

CREATE A PROJECT WITH US

Maker’s Row as a platform helps to be part of jewelry producers and factories with enterprise professionals to group and examine enterprise tendencies, which helps to stay ahead of the rivals and adapt most interesting practices.

image credit score rating: pinterest

Conclusion

Subsequently, by implementing jewelry manufacturing facility prime quality administration procedures throughout the jewelry manufacturing course of, it’d help to continuously improve and provide prime quality jewelry objects. And sourcing prime quality provides from offers moreover helps. This helps in reaching purchaser expectations and jewelry manufacturing necessities whereas making a loyal purchaser base. Meeting enterprise necessities helps factories to mark their presence accessible available in the market by means of top of the range manufacturing. It moreover helps to cut back returns and dissatisfaction, which leads to optimistic phrase of mouth and helps in getting new purchasers.

You Can Moreover Be taught..